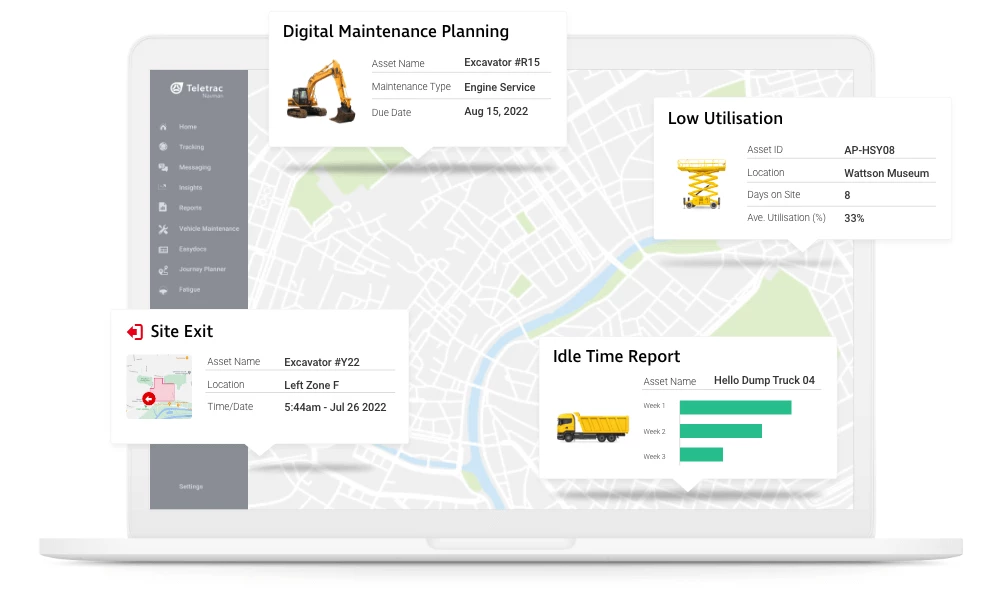

Spot issues before they become serious problems with real-time visibility into equipment usage, engine fault codes, mileage and more. Eliminate unnecessary downtime by knowing the assets that need maintenance and where they are located. Stay on top of pre-use inspections and ensure your operators are using safe and fully maintained equipment.

Build Your Solution Explore Software

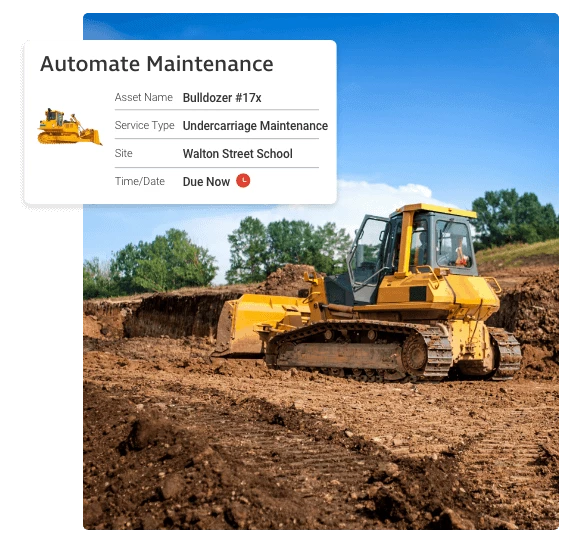

Automate your equipment maintenance schedule with digital workflows designed to eliminate paper-based processes and streamline your maintenance operation. Eliminate time spent on data-entry and other tedious paperwork. With customizable alerts and notifications, maintenance managers can stay on top of essential maintenance activities and respond quickly to unexpected issues.

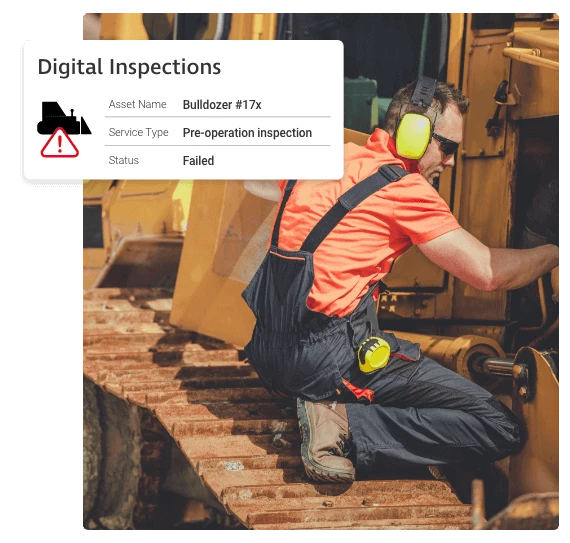

Perform pre- and post-use inspections on your mobile device and instantly submit failed checks. The easy-to-use application guides operators through the inspection steps and provides instructions on what to do should they identify points of failure. Data is instantly captured in the equipment management software so action can be taken quickly, minimising downtime.

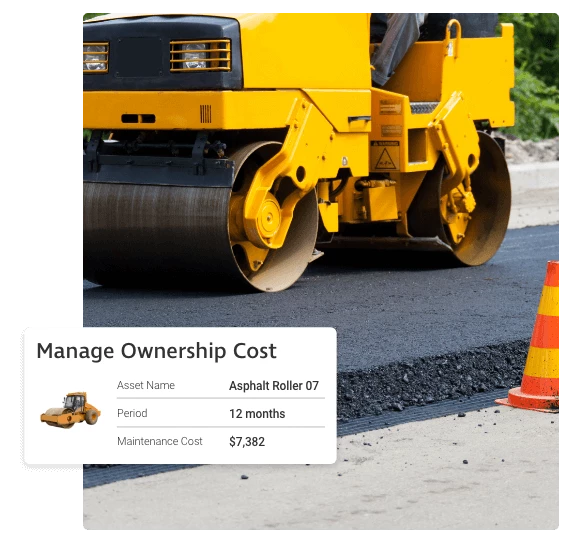

Use equipment data to accurately measure and understand total cost of ownership. By tracking usage and monitoring maintenance patterns and cost in real-time, businesses can make more informed decisions on equipment replacement cycles.

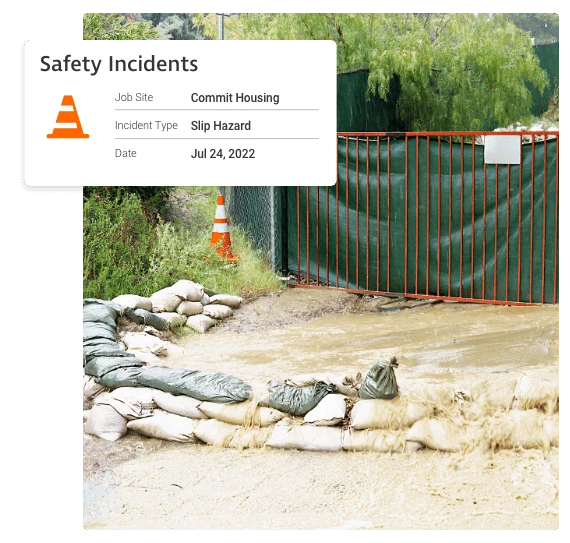

Leverage digital inspections to improve equipment safety and monitor maintenance needs in real-time to ensure your equipment is safe for use. The flexible solution also enables you to digitise your safety incident log and operator management process, so you can be confident that operator licenses and training is up to date.

There are a large number of questions that constantly get asked about equipment maintenance. Here is a short compilation of answers to some of the questions to help you better understand topics surrounding equipment maintenance.

Preventative maintenance refers to the regular and routine maintenance required to keep a fleet of vehicles or equipment in peak working condition. It’s a necessary strategy to prevent unplanned downtime and the costs associated with unanticipated asset failure.

Predictive maintenance is the act of using historical data to improve fleet efficiency. Predictive maintenance tells fleet managers not only what their trucks are doing, but what they will do in the future. Different equipment performs different tasks and therefore they have different needs. Predictive maintenance can help identify which equipment needs maintenance more regularly and which problem areas can occur frequently.

Fleet maintenance is the monitoring and servicing of equipment and vehicles to prevent breakdowns and malfunctions and extend the life of assets. Preventative maintenance follows a pre-planned schedule, whereas predictive maintenance is based on real-time data on equipment health and performance.

Computerised Maintenance Management System (CMMS) helps make maintenance operations more reliable and simpler to manage – resulting in a lighter workload, increased productivity with staff, and increased protection of assets against excessive wear and tear or unexpected breakdowns.

Fleet maintenance is the process of keeping your vehicles operating in a good enough condition so that they are safe, reliable and can stay on the road longer. Developing a preventative maintenance program is an integral part of managing a fleet and helps businesses reduce operating costs and improve vehicle inspection outcomes, among other benefits.